Zirconium alloys are widely used in PWR, CANDU and BWR nuclear fission reactors as the nuclear fuel cladding and pressure tube material. Zr has a relatively low neutron absorption cross section and good mechanical properties. However, Zr alloys degrade during their lifetime in the reactor due to a number of factors including oxidation, hydrogen embrittlement and irradiation damage. Understanding these mechanisms is key to improving Zr alloy performance.

The oxidation rate of Zr alloys has been shown to depend strongly on alloy composition, and small changes in alloy chemistry may significantly alter oxidation rate. This is a limiting factor in the lifetime of Zr alloy fuel assemblies and other reactor components. Understanding the mechanism underlying this effect is key to improving fuel utilisation, reducing reactor refuelling outages, and to reducing waste.

Under irradiation, Zr alloy nanoscale chemistry can change due to precipitation of alloying elements formed under irradiation. These precipitates are often too small for most microscopy techniques to provide a quantitative analysis. Atom probe tomography is a technique well suited to spatially resolve and allow chemical characterisation of nanoscale precipitates.

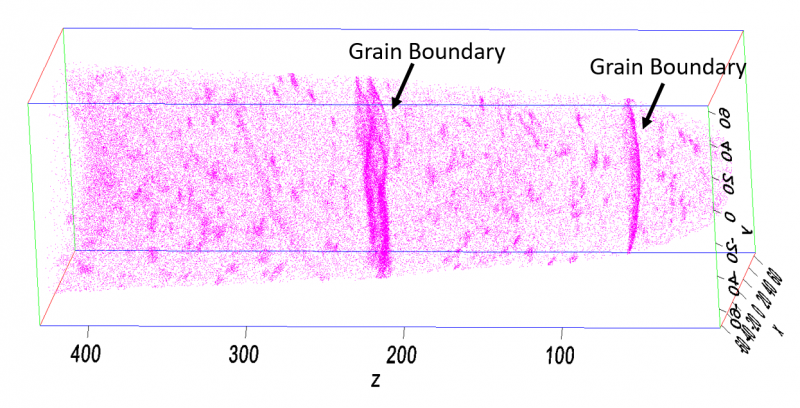

APT data showing the Fe distribution in a sample of Zr-2.5%Nb pressure tube material neutron irradiated at 325°C for 2400 days. The nanoscale clustering of Fe is a result of irradiation, and Fe is also seen segregated to grain boundaries.

A.Callow